Understanding the Different Types of Milling Equipment

Milling equipment refers to machines designed to grind, crush, or cut materials into smaller, more manageable pieces or fine powders. These machines are crucial in many industries, including industrial, agriculture, chemical, and mineral.

4 Common Types of Milling Equipment

The primary purpose of milling equipment is to reduce the size of raw materials, making them suitable for further processing or end-use applications. This size reduction enhances the material’s properties, such as its reactivity, surface area, and flowability, which are important for producing consistent, high-quality products. Milling equipment also plays a key role in blending and homogenizing materials, ensuring uniformity in the final product.

Selecting the right milling equipment is essential for achieving efficient and high-quality production. With a variety of milling machines available, each designed to handle specific materials and processes, understanding their features will help you make an informed choice.

Ball Mills

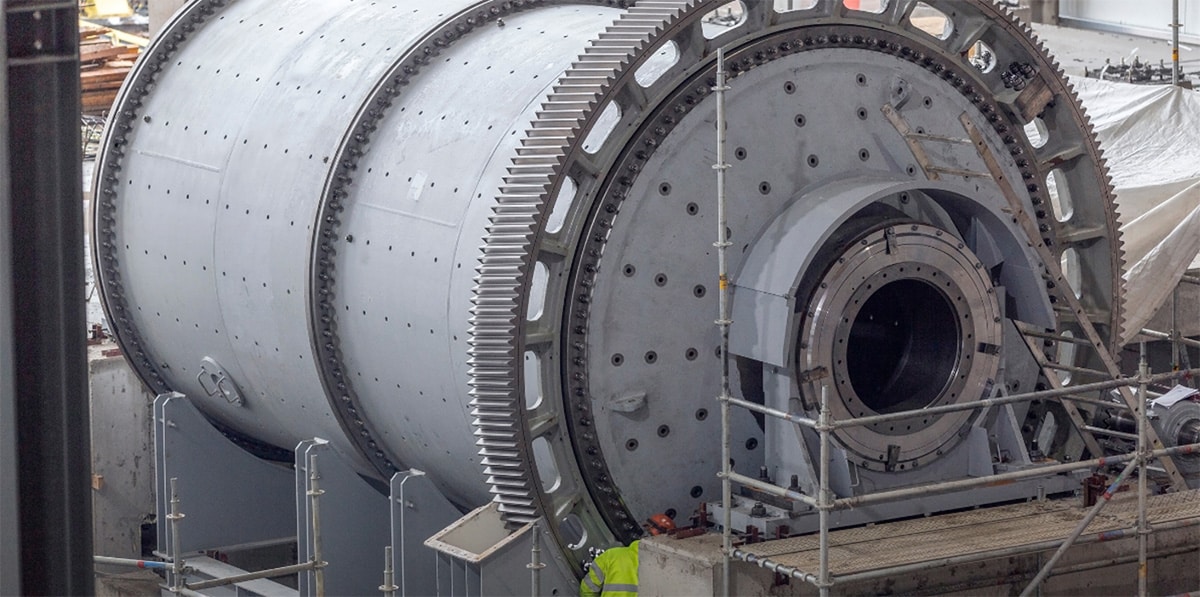

What Are Ball Mills?

Ball mills are cylindrical devices used to grind materials into fine powder. They operate by rotating a cylinder filled with grinding media (such as balls) and the material to be milled. The rotation of the cylinder causes the balls to fall onto the material, crushing and pulverizing it into a fine powder.

Applications and Benefits

Ball mills are ideal for producing fine and uniform particle sizes, making them suitable for use in the mining, ceramics, and chemical industries. They are highly efficient for grinding brittle materials and can handle both dry and wet milling processes.

Jet Mills

What Are Jet Mills?

Jet mills use high-velocity jets of air or steam to collide particles against each other, resulting in ultra-fine grinding. They do not use any mechanical grinding media. Instead, the particles are accelerated by the air jets and collide with each other, leading to size reduction.

Applications and Benefits

Jet mills are perfect for achieving extremely fine particle sizes and are commonly used in the pharmaceutical, cosmetic, and chemical industries. They are ideal for heat-sensitive materials since no mechanical heat is generated during the process.

Roller Mills

What Are Roller Mills?

Roller mills use cylindrical rollers to crush and grind materials. The material is fed between two rollers that rotate in opposite directions, exerting compressive force. This method is efficient for breaking down grains and other materials into uniform sizes.

Applications and Benefits

Roller mills are excellent for producing uniform particle sizes and are widely used in the food processing, brewing, and mineral processing industries. They offer high efficiency and can handle a range of materials, from grains to ores.

Air Classifying Mills

What Are Air Classifying Mills?

Air classifying mills combine two-stage closed-circuit grinding with internal air classification for precise and efficient particle size reduction. They use high-speed impact and a built-in classifier to separate fine particles from coarse ones. This ensures a consistent and controlled particle size distribution.

Applications and Benefits

Air classifying mills are highly versatile and suitable for a range of materials, including chemicals, feed additives, and minerals. They are especially useful for applications requiring ultra-fine particle sizes and tight particle size distributions. The built-in classifier ensures consistent quality and minimizes the need for external sieving.

Selecting the Right Milling Equipment

- Assess your material. The first step in choosing the right milling equipment is to understand the properties of your material. Consider factors such as hardness, moisture content, and particle size requirements.

- Determine your production needs. Evaluate your production volume and the desired particle size distribution. This will help you identify the equipment that can meet your throughput and quality standards.

- Consider efficiency and cost. Balance the efficiency of the milling equipment with the cost of operation and maintenance. Look for machines that offer a good return on investment and align with your budget.

Discover Custom Milling Solutions with M&M Milling

Looking for expert advice on choosing the right milling equipment for your needs? At M&M Milling, we specialize in custom toll and contract manufacturing, offering a wide range of milling solutions tailored to your requirements. Our experienced milling team is dedicated to providing high-quality, efficient, and reliable milling services that meet the specific needs of your industry. Contact us today to learn how we can help you achieve all your production goals with precision and reliability.